eCOUNT Electronic has made a name for itself by procuring discontinued or hard-to-find parts. In this area, we work with certified suppliers, internal test equipment, as well as with well-known test houses after consultation with the customer.

Our incoming inspections are carried out in accordance with ISO certified process and take into account not only the general condition of the components but also mechanical (dimensions, construction, etc.). We obtain a highly qualified statement about the condition of the parts.

If required, moisture-sensitive components are tempered in our drying oven according to JEDEC specifications and subsequently injected into ESD packaging compliant with MSL.

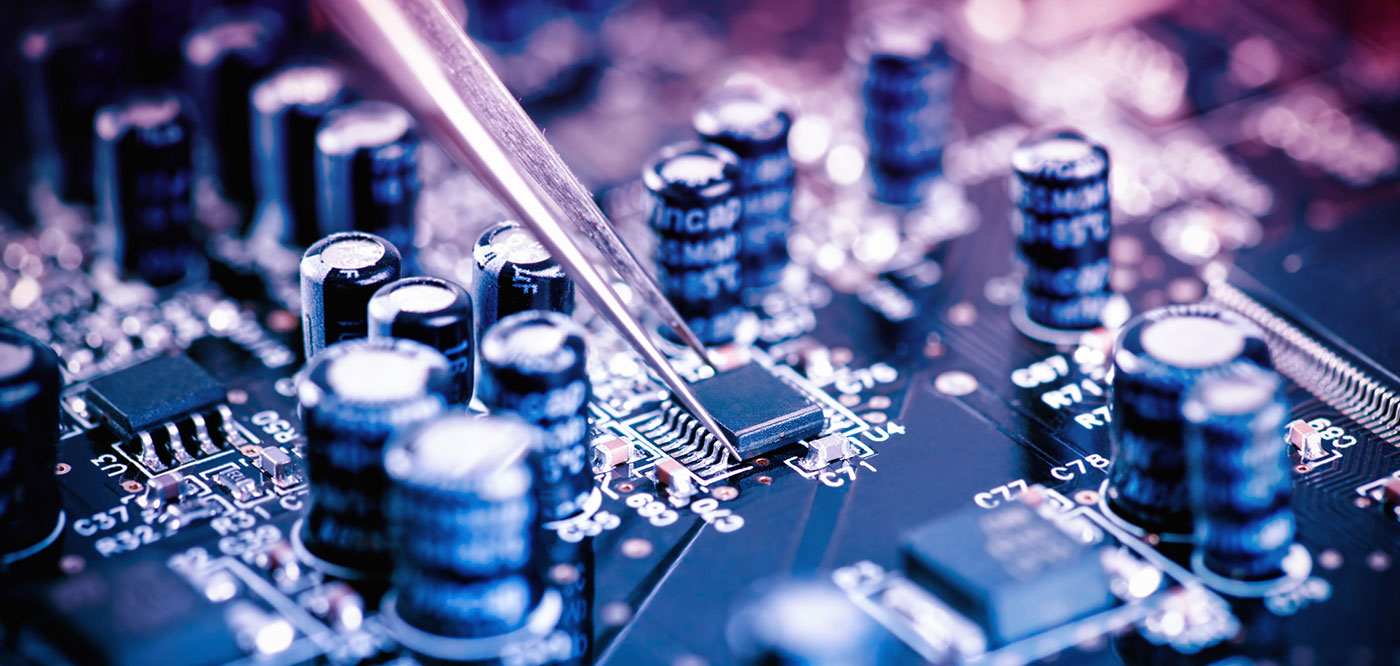

Especially with older components everybody is faced with the problem to determine the solderability and function of electronic components.

In this case we offer our partners solderability and function tests . By a fully automatic solderablility test the specific wetting forces of each single component pin can be determined and filed.

We also check the function of electronic parts via specific test methods which include parametric tests, etc. During the test potential error sources are revealed and the required test depth is ensured.

Upon customer request or as required, the components are either subjected to an X-ray inspection procedure or chemically opened. The components are checked for originality based on reference samples or data sheet specifications.